The Ultimate Guide to Industrial Laser Marking Machines

As technology evolves and industries continue to advance, the need for precise and efficient marking solutions has become crucial for Metal Fabricators worldwide. One of the most innovative tools that have revolutionized the marking process is the industrial laser marking machine.

What is an Industrial Laser Marking Machine?

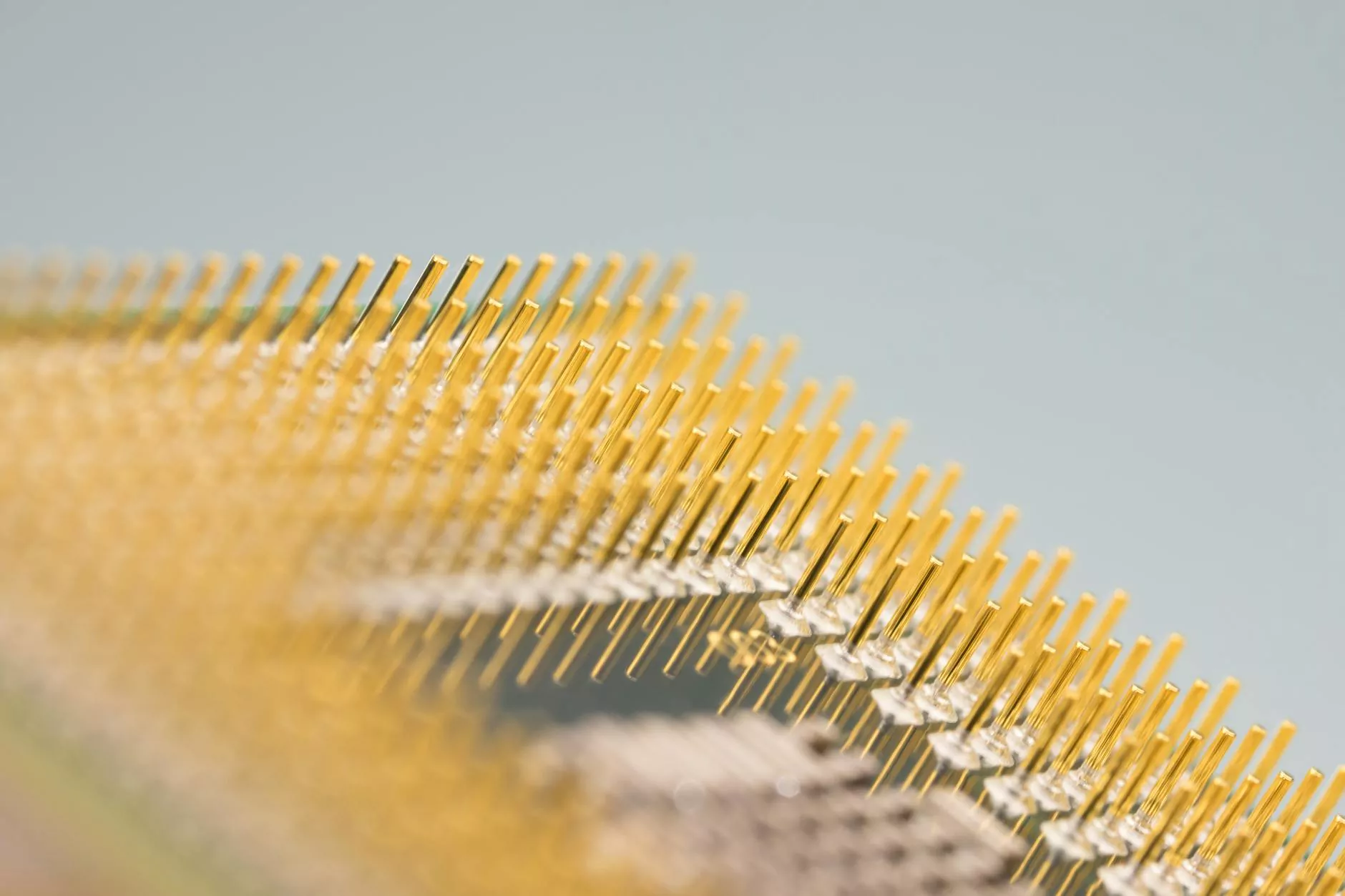

An industrial laser marking machine is a high-precision tool used in various industries, particularly by Metal Fabricators, to mark and engrave materials with unparalleled accuracy and speed. Unlike traditional methods like stamping or engraving, laser marking offers a non-contact process that provides clear, permanent markings.

Key Features of Industrial Laser Marking Machines

There are several key features that make industrial laser marking machines stand out:

- Precision: Laser marking machines ensure precise markings, even on complex shapes and materials.

- Speed: These machines can mark products quickly, increasing efficiency in production lines.

- Versatility: Industrial laser marking machines can mark on a wide range of materials, including metals, plastics, and ceramics.

- Durability: Laser markings are resistant to wear, ensuring longevity and readability of the marks over time.

Applications of Industrial Laser Marking Machines in Metal Fabrication

For Metal Fabricators, industrial laser marking machines play a crucial role in various applications:

- Product Identification: Laser marking enables Metal Fabricators to add serial numbers, barcodes, and logos to their products for traceability.

- Quality Control: Laser markings can be used to indicate quality certifications, ensuring compliance with industry standards.

- Customization: Metal Fabricators can use laser marking machines to offer personalized engravings for their clients, adding value to their products.

Choosing the Right Industrial Laser Marking Machine

When selecting an industrial laser marking machine for your Metal Fabrication business, consider the following factors:

- Laser Type: The two main types of lasers used in marking machines are fiber lasers and CO2 lasers, each with its advantages depending on the material being marked.

- Marking Area and Speed: Evaluate the size of the marking area and the speed of the machine to ensure it meets your production requirements.

- Software Capabilities: Look for machines that offer user-friendly software for designing and controlling the markings.

Benefits of Using Industrial Laser Marking Machines

The adoption of industrial laser marking machines in Metal Fabrication businesses can lead to several benefits:

- Increased Efficiency: Laser marking machines streamline the marking process, reducing production time and costs.

- Enhanced Product Quality: The precision of laser markings ensures high-quality and consistent results.

- Improved Traceability: Laser markings provide a reliable method for tracking products through the manufacturing process.

Conclusion

Industrial laser marking machines have become indispensable tools for Metal Fabricators looking to achieve precision, efficiency, and quality in their marking processes. By investing in the right laser marking machine, businesses can stay ahead in today's competitive market and deliver superior products to their customers.

Explore the advanced industrial laser marking machines available at DPLaser.com to elevate your Metal Fabrication capabilities and take your business to the next level!