Leading Metal Fabricators and the Premier CNC Lathe Turning Parts Factory at deepmould.net

The manufacturing industry has always been the backbone of modern economic development, fueling innovations across countless sectors, from aerospace to automotive, electronics to construction. Within this vibrant ecosystem, metal fabricators play a crucial role by transforming raw metal materials into components that meet the highest standards of precision, durability, and functionality. At the forefront of this industry specialization is the deepmould.net platform — a trusted metal fabricator known for its prowess in delivering superior cnc lathe turning parts factory solutions.

Unveiling the Role of Metal Fabricators in Modern Industry

Metal fabricators are artisans and engineers dedicated to shaping, cutting, assembling, and finishing metal into usable products and parts. Their work requires a combination of advanced technical expertise, innovative technology, and strict quality control. These specialists cater to a diverse array of industries, including:

- Automotive — from engine parts to body panels

- Aerospace — requiring high-strength, lightweight components

- Electronics — intricate metal enclosures and connectors

- Construction — structural steel and decorative elements

- Medical equipment — precision-machined hardware

In each of these areas, the demand for high-precision, high-quality metal parts is critical. This generates an ongoing need for innovation in machining techniques and manufacturing processes, making the role of specialized metal fabricators fundamental to progress and success.

The Precision and Efficiency of a cnc lathe turning parts factory

Among the critical services offered by top-tier metal fabricators is the manufacturing of cnc lathe turning parts. These components are produced using advanced CNC (Computer Numerical Control) lathes, which provide exceptional accuracy, repeatability, and efficiency, enabling manufacturers to meet stringent specifications and tight deadlines.

What Makes a cnc lathe turning parts factory Superior?

- State-of-the-Art Technology: Use of high-precision CNC machines designed for complex machining operations.

- Expert Workforce: Skilled engineers and machinists with extensive experience in CNC turning processes.

- Quality Control: Rigorous inspection protocols, including 3D measurement and surface finish analysis, ensuring each part meets international standards.

- Material Versatility: Capability to work with various metals such as stainless steel, aluminum, brass, copper, and specialty alloys.

- Customization: Ability to produce custom designs tailored to specific project requirements with quick turnaround times.

Why Choose deepmould.net for Your cnc lathe turning parts Needs?

deepmould.net distinguishes itself from competitors by combining cutting-edge technology with unmatched customer service. As a trusted metal fabricator, we specialize in delivering precision cnc lathe turning parts factory solutions that meet the highest standards in quality and efficiency.

Core Strengths of deepmould.net

- End-to-End Manufacturing Expertise: From prototyping and small batch production to large-volume manufacturing, we have the capacity to handle diverse project scopes.

- Advanced Raw Material Sourcing: We acquire only premium-quality metals ensuring durability and performance of every product.

- Innovative Manufacturing Techniques: Incorporating the latest CNC technology, automation, and quality management systems.

- Fast Turnaround Times: Optimized workflows to deliver products precisely when you need them without compromising quality.

- Cost-Efficiency: Combining high quality with competitive pricing, maximizing your return on investment.

Application of CNC Lathe Turning Parts in Various Industries

The versatility of cnc lathe turning parts makes them indispensable across multiple industries, fueling innovation and improving performance. Here are some key applications:

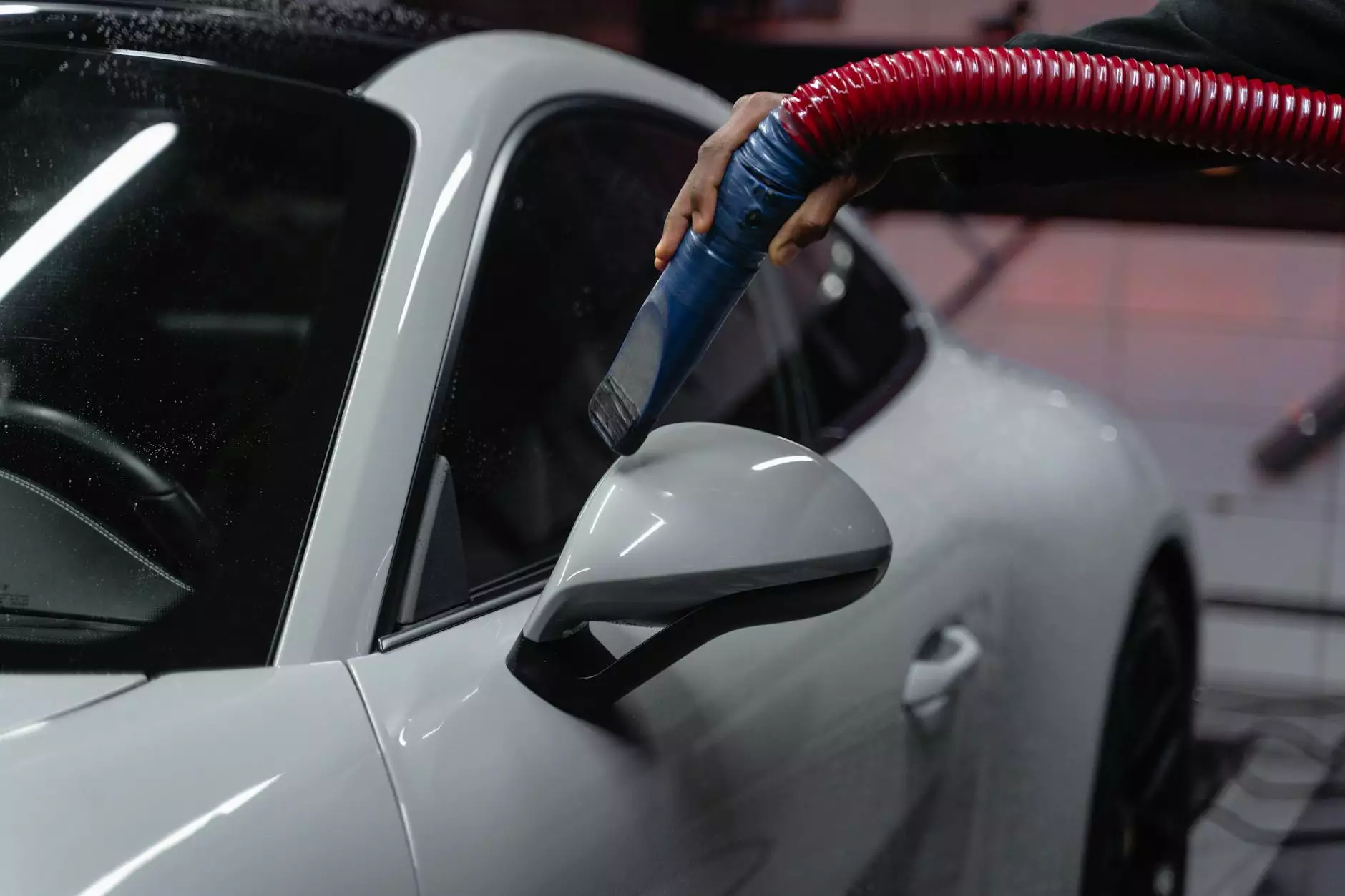

Automotive Industry

Precision machined automotive components, such as shafts, gears, and threaded fasteners, rely heavily on CNC lathe turning technology. These parts require exacting tolerances and surface finish quality to ensure optimal vehicle performance and safety.

Aerospace Sector

In aerospace, components must withstand extreme conditions. CNC turning allows for manufacturing lightweight yet robust parts like compressor blades, structural fittings, and engine components, adhering to strict standards such as FAA regulations.

Electronics and Communications

Manufacturers require tiny, intricate metal parts for enclosures, connectors, and heat sinks. CNC lathe turning parts provide the precision and consistency essential for these delicate applications.

Medical Devices

Medical instruments and implants demand sterile, reliable, and highly precise parts. CNC turning factories, including deepmould.net, excel at producing complex geometries with tight tolerances, critical for patient safety and device effectiveness.

Industrial Machinery and Equipment

Heavy-duty components, coupling parts, and hydraulic fittings are produced with CNC turning for enhanced lifespan and performance, operating reliably in demanding industrial environments.

Advantages of Partnering with deepmould.net for cnc lathe turning parts factory

- Unmatched Precision: Leveraging the latest CNC technology ensures high accuracy, essential for sophisticated engineering projects.

- Rapid Prototyping and Development: Shorten product development cycles with fast-turnaround manufacturing processes.

- Engineering Support: Our team offers detailed consultation to optimize designs for manufacturability and cost-efficiency.

- Comprehensive Quality Management: Implementation of ISO-certified processes guarantees consistent product quality.

- Flexible Production Capabilities: From prototypes to mass production, we scale seamlessly to meet your project demands.

The Future of Metal Fabrication and CNC Turning Technology

Technological evolution continues to shape the future of metal fabrication, with innovations like AI-driven automation, advanced materials, and smart manufacturing opening new possibilities. For example:

- Smart CNC Machines: Equipped with AI and IoT connectivity for real-time monitoring and adaptive machining.

- Material Advancements: Use of composite metals for enhanced strength-to-weight ratios.

- Digital Twin and Simulation: Virtual testing to refine designs prior to production, reducing waste and costs.

By staying at the forefront of these developments, deepmould.net ensures enhanced capabilities, reduced lead times, and superior product quality for all our clients’ cnc lathe turning parts.

Conclusion: Elevate Your Manufacturing Projects with deepmould.net

In the highly competitive landscape of industrial manufacturing, partnering with a reliable, innovative, and quality-focused metal fabricator is vital. With extensive experience, cutting-edge CNC turning technology, and a dedicated team, deepmould.net stands out as the best choice for your cnc lathe turning parts factory needs.

Whether you require small batch prototypes or large-scale production, our commitment to excellence guarantees parts that meet or surpass your expectations. Invest in your project’s success by choosing a partner that values precision, efficiency, and superior craftsmanship — choose deepmould.net for exceptional metal fabrication solutions.