CSX Intermodal Northwest Ohio Process Area Expansion

Portfolio

Overview

The CSX Intermodal Northwest Ohio process area expansion project, undertaken by McKenna John J Architect, is a remarkable example of excellence in Heavy Industry and Engineering - Architecture. This project showcases the firm's commitment to delivering innovative and practical architectural solutions.

Project Details

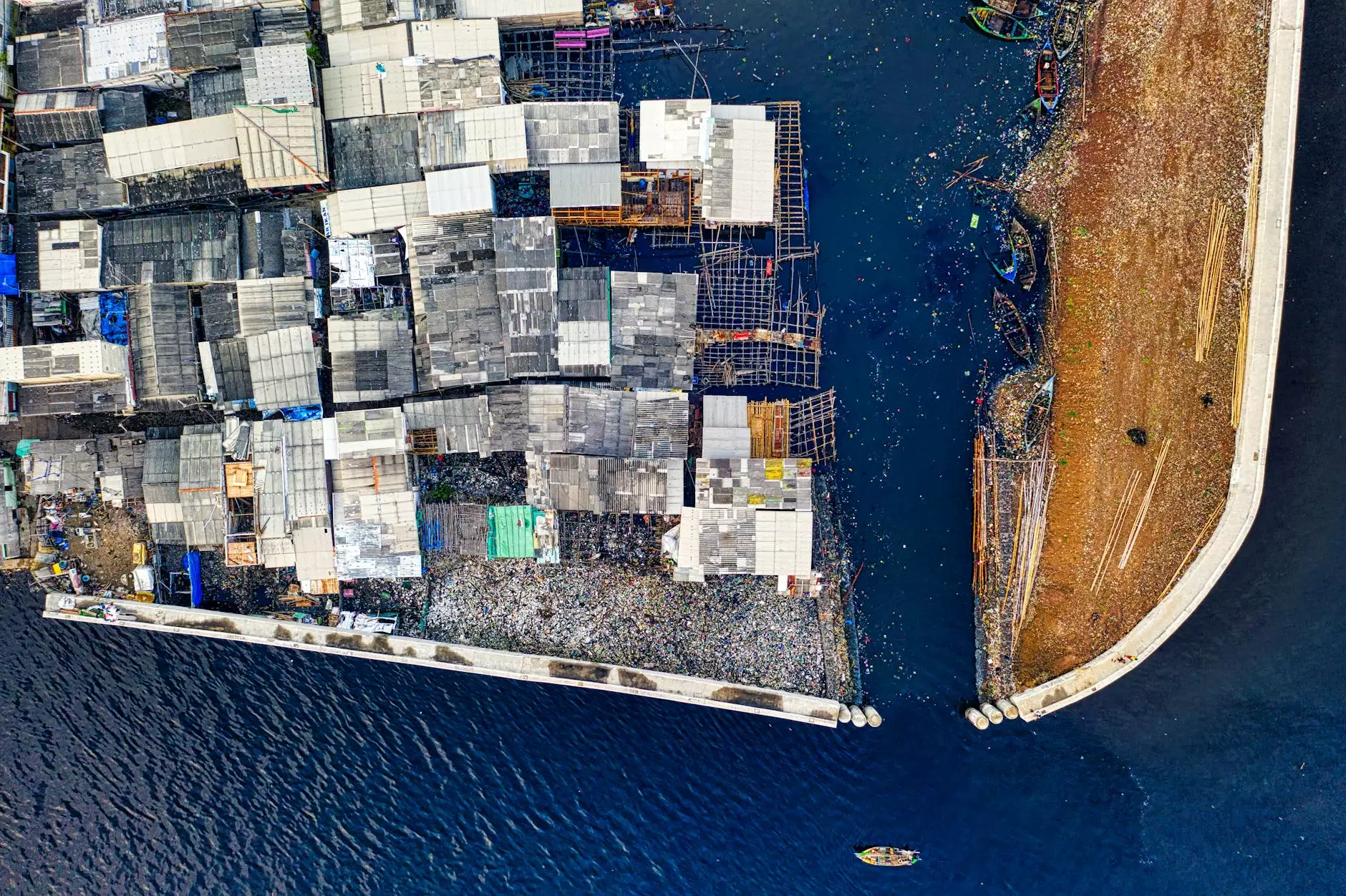

The CSX Intermodal Northwest Ohio process area expansion was a major undertaking with the goal of expanding the existing facilities and optimizing the process area to enhance efficiency and throughput. The project encompassed the construction of state-of-the-art storage facilities, truck access points, and high-tech handling equipment.

Challenges Faced

Like any large-scale project, the CSX Intermodal Northwest Ohio process area expansion faced several challenges that required meticulous planning and problem-solving expertise. Some of the key challenges included:

- Space Optimization: The expansion had to be strategically planned to make the most efficient use of the available space while complying with local regulations and safety guidelines.

- Integration: The newly constructed facilities had to seamlessly integrate with the existing infrastructure, ensuring a harmonious flow of operations and minimal disruption during the expansion process.

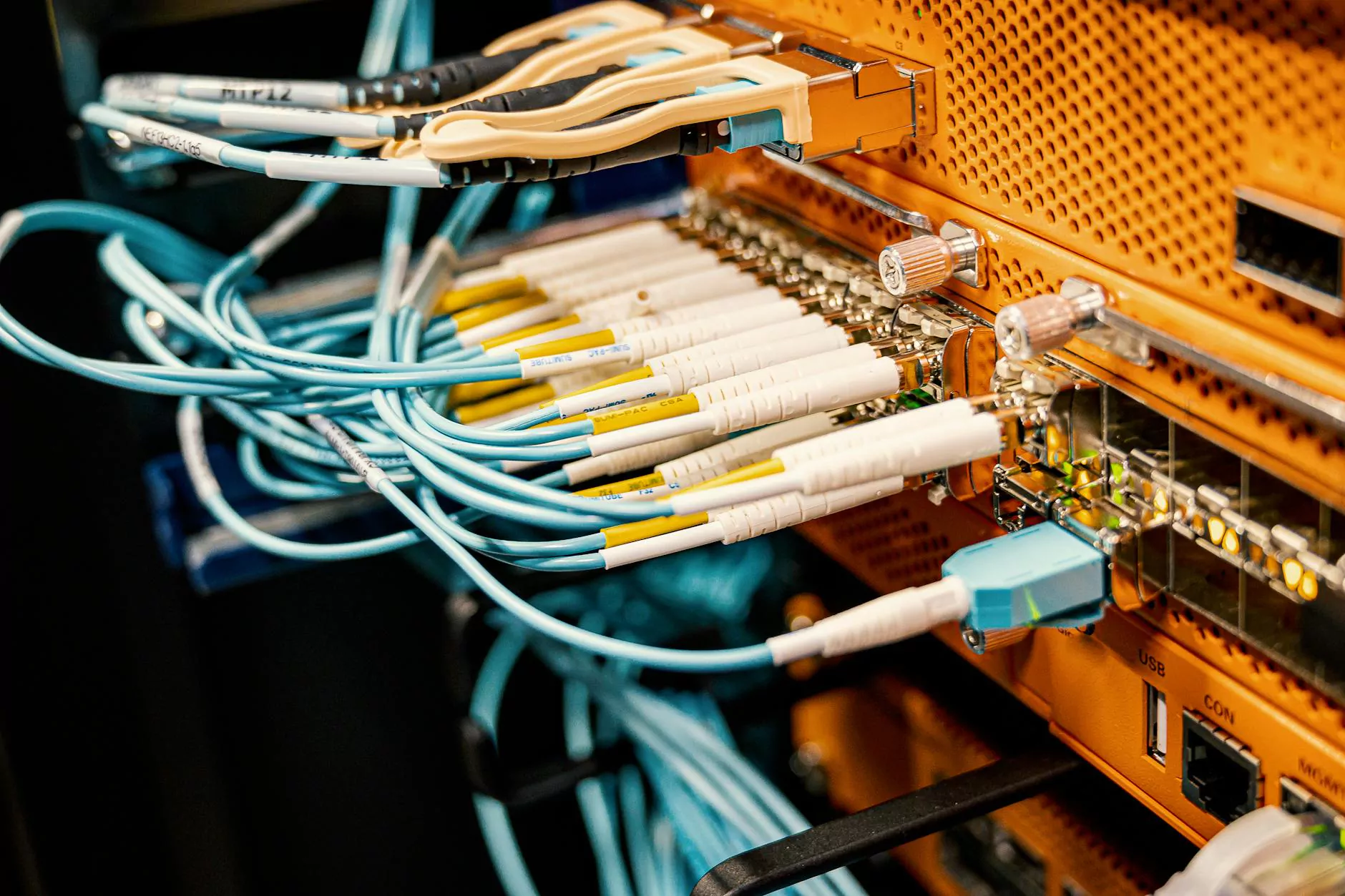

- Technology Integration: The project involved the integration of cutting-edge technologies to improve overall efficiency and productivity. The architecture needed to accommodate the integration of automation systems, advanced handling equipment, and optimized storage solutions.

- Sustainability: Maintaining sustainable practices was a crucial aspect of the project. The architecture needed to incorporate energy-efficient designs, efficient waste management systems, and eco-friendly materials to minimize the environmental impact.

Architectural Solutions

The McKenna John J Architect team devised innovative architectural solutions to address the challenges faced during the CSX Intermodal Northwest Ohio process area expansion. These solutions leveraged advanced technologies, strategic planning, and a deep understanding of heavy industry needs:

Space Optimization

To make the most of the available space, McKenna John J Architect implemented a multi-tiered storage system, utilizing vertical space efficiently without compromising on accessibility. This innovative approach not only increased storage capacity but also optimized material handling processes.

Integration

The architectural design seamlessly integrated the new facilities with the existing infrastructure. The team carefully planned the layout to ensure smooth flow and minimal disruption during construction. The expanded areas were thoughtfully connected to existing transport networks and utility systems.

Technology Integration

McKenna John J Architect incorporated advanced automation systems, intelligent handling equipment, and optimized storage solutions into the architectural design. By leveraging the latest technologies, the project achieved enhanced productivity, reduced manual labor, and improved efficiency throughout the process area.

Sustainability

With a commitment to sustainability, the project incorporated various green initiatives. McKenna John J Architect integrated energy-efficient designs, implemented renewable energy sources, and prioritized the use of eco-friendly materials. The architecture also incorporated efficient waste management systems, reducing the project's environmental footprint.

Conclusion

The CSX Intermodal Northwest Ohio process area expansion project showcases McKenna John J Architect's expertise in Heavy Industry and Engineering - Architecture. Through meticulous planning and innovative solutions, the project successfully optimized the space, integrated seamlessly with existing infrastructure, leveraged advanced technologies, and prioritized sustainability. The result is a state-of-the-art facility that exceeds client expectations and sets a new standard in heavy industry architecture.